HS Code:

84138100

Lieferbar:

3-4 Werktage

Electric barrel pump set – acids & mild alkalis

Designed for safe, efficient filling of aqueous acids/alkalis and cleaning media. The internally ventilated universal motor (230 V or 115 V, 50/60 Hz) is double insulated (protection class II) and features overcurrent protection with undervoltage release. The PP pump unit with HC shaft offers good chemical resistance and can be quickly integrated via G 1¼" and 1" (DN 25).

Technical data – Drive

| Service | supply | frequency | degree of protection | protection class | Cables/plugs | protective functions |

|---|---|---|---|---|---|---|

| 640 W | 230 V or 115 V | 50/60 Hz | IP 24 | II (double insulated) | 5 m, Schuko plug | Overcurrent protection, undervoltage release |

Technical data – Pumping station & performance

| pumping station | Outer diameter | Shaft | connection thread | hose connection | Flow rate* | delivery head* | Maximum viscosity | maximum density |

|---|---|---|---|---|---|---|---|---|

| Polypropylene (PP) | 41 mm | HC | G 1¼" | 1" (DN 25) | 93 l/min | 11 m | 600 mPa·s | 1.5 |

* Rotor operation, reference values.

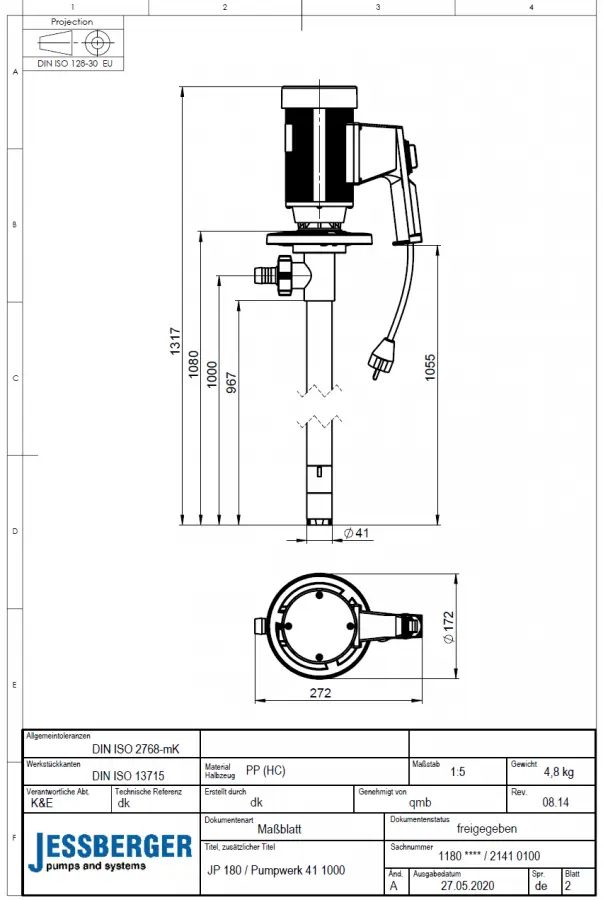

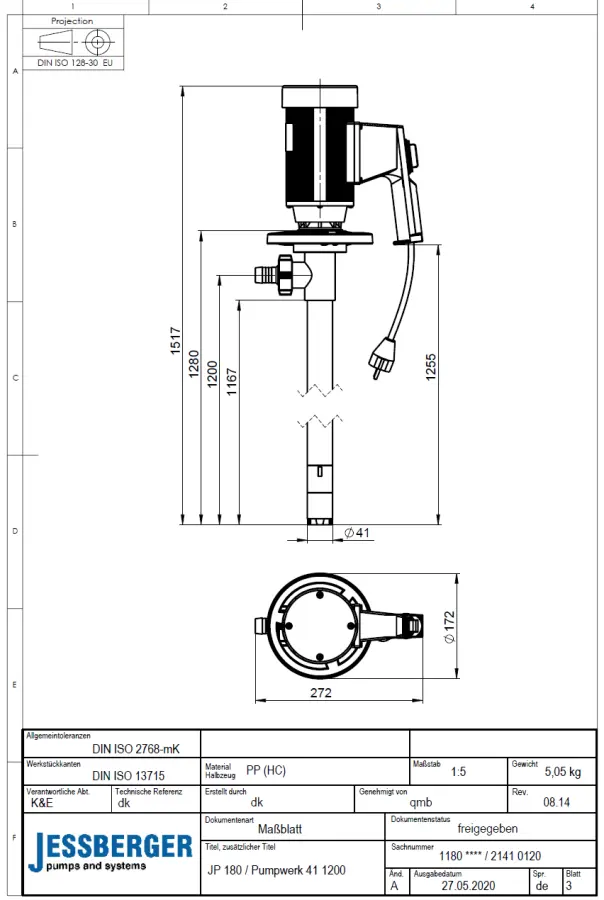

immersion tube lengths

| immersion tube length | Suitable for |

|---|---|

| 1000 mm | 200-liter drum |

| 1200 mm | IBC (1000 l) |

Scope of delivery

2 m PVC hose 1" (NW 25)

2 × stainless steel hose clamps

1 × Polypropylene fuel nozzle 1" (DN 25)

Suitable media (examples)

Formic acid (up to 50%), ammonia, boric acid (diluted), distilled water, fertilizer solutions, acetic acid (up to 80%), fruit acids, lactic acid, citric acid, hydrogen peroxide, photo developer, copper chloride, battery acid (sulfuric acid 20%), adipic acid (aqueous), arsenic acid (aqueous), ascorbic acid (aqueous), aspartic acid (aqueous).

benefits

Compact, powerful set for aqueous acids/alkalis

IP 24-protected motor, double insulated

Good durability thanks to PP pump mechanism and HC shaft

Two dip tube lengths for barrels and IBCs

Delivered complete – quick, clean installation

Note

Not suitable for conveying combustible media or for use in hazardous areas.

Check material compatibility (PP, seals, hose) and temperature limits before use.

Polypropylene is generally resistant to aqueous acids/alkalis, salts, and many organic media; highly concentrated oxidizing acids are not suitable.