HS Code:

73072910

Lieferbar:

sofort ( 2-3 Werktage )

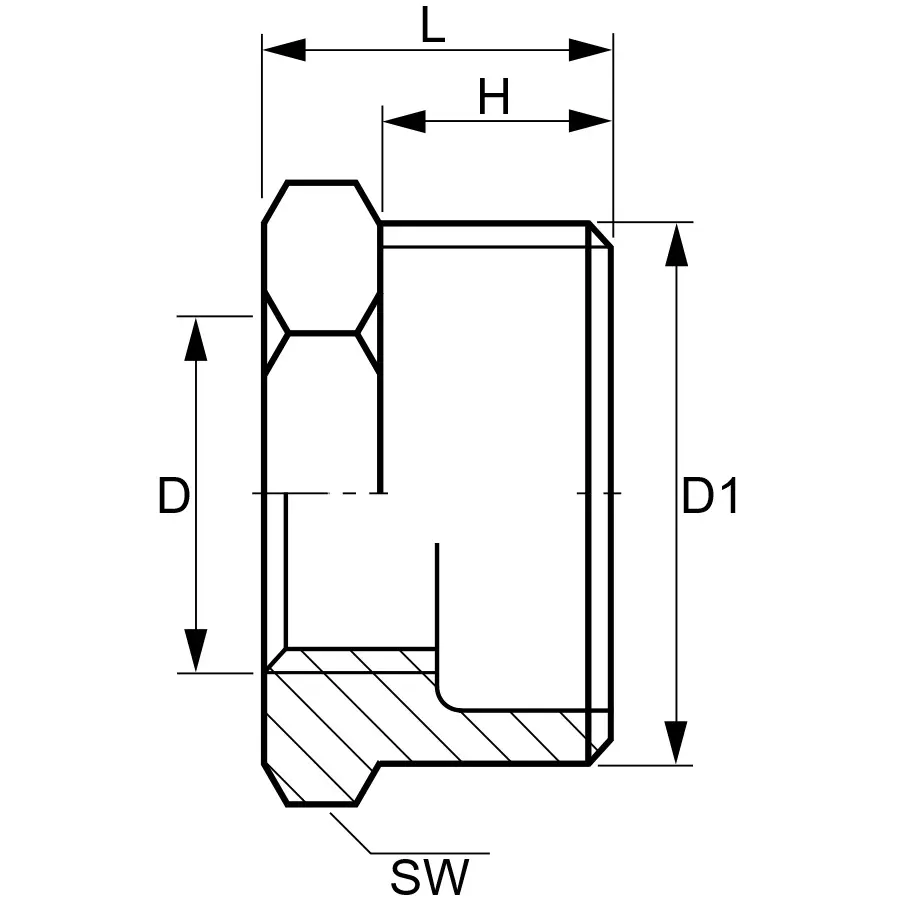

Reducing ring, external thread x internal thread, stainless steel

This reducer ring made of high-quality AISI 316 V4A stainless steel (material 1.4408) offers reliable adaptation between different pipe dimensions thanks to its conical BSP-R thread. Manufactured in accordance with ISO 4144 and featuring CNC-milled Whitworth threads, it guarantees a precise fit. The material is resistant to aggressive media and meets the requirements for drinking water installations in accordance with DVGW W541.

Technical data

| feature | Execution |

|---|---|

| connection | External thread x Internal thread |

| Thread | BSP-R (tapered) / Rp (cylindrical), ISO 7/1, DIN 2999, BS21 |

| temperature range | –4 °F to 392 °F |

| Working pressure (PN) | max. 20 bar |

| Material | Stainless steel AISI 316 V4A (1.4408) |

| standards | ISO 4144, EN 10213-4 |

| Properties | Corrosion-resistant, suitable for drinking water, resistant to acids, alkalis, chlorides |

size options

| Variant | Internal thread (Rp) | External thread (R) | H (mm) | L (mm) | SW (mm) |

|---|---|---|---|---|---|

| 1/4" x 1/8" | Rp 1/8" (9.73 mm) | R 1/4" (13.16 mm) | 10 | 16 | 14 |

| 3/8" x 1/8" | Rp 1/8" (9.73 mm) | R 3/8" (16.66 mm) | 10 | 16.5 | 18 |

| 3/8" x 1/4" | Rp 1/4" (13.16 mm) | R 3/8" (16.66 mm) | 10 | 16.5 | 18 |

| 1/2" x 1/8" | Rp 1/8" (9.73 mm) | R 1/2" (20.95 mm) | 13 | 19.5 | 22 |

| 1/2" x 1/4" | Rp 1/4" (13.16 mm) | R 1/2" (20.96 mm) | 12 | 19.5 | 22 |

| 1/2" x 3/8" | Rp 3/8" (16.66 mm) | R 1/2" (20.96 mm) | 12 | 19.5 | 22 |

| 3/4" x 1/8" | Rp 1/8" (9.73 mm) | R 3/4" (26.44 mm) | 15 | 21 | 28 |

| 3/4" x 1/4" | Rp 1/4" (13.16 mm) | R 3/4" (26.44 mm) | 14 | 21 | 28 |

| 3/4" x 3/8" | Rp 3/8" (16.66 mm) | R 3/4" (26.44 mm) | 14 | 21 | 28 |

| 3/4" x 1/2" | Rp 1/2" (20.96 mm) | R 3/4" (26.44 mm) | 14 | 21 | 28 |

| 1" x 1/8" | Rp 1/8" (9.73 mm) | R 1" (1.32 in) | 16 | 24.5 | 35 |

| 1" x 1/4" | Rp 1/4" (13.16 mm) | R 1" (1.32 in) | 17 | 24 | 35 |

| 1" x 3/8" | Rp 3/8" (16.66 mm) | R 1" (1.32 in) | 16 | 24 | 35 |

| 1" x 1/2" | Rp 1/2" (20.96 mm) | R 1" (1.32 in) | 16 | 24 | 35 |

| 1" x 3/4" | Rp 3/4" (26.44 mm) | R 1" (1.32 in) | 16 | 24 | 35 |

| 1 1/4" x 1/8" | Rp 1/8" (9.73 mm) | R 1 1/4" (41.91 mm) | 20 | 30 | 43 |

| 1 1/4" x 1/4" | Rp 1/4" (13.16 mm) | R 1 1/4" (41.91 mm) | 17 | 25.5 | 44 |

| 1 1/4" x 3/8" | Rp 3/8" (16.66 mm) | R 1 1/4" (41.91 mm) | 16 | 23 | 43 |

| 1 1/4" x 1/2" | Rp 1/2" (20.96 mm) | R 1 1/4" (41.91 mm) | 19 | 27 | 43.5 |

| 1 1/4" x 3/4" | Rp 3/4" (26.44 mm) | R 1 1/4" (41.91 mm) | 18 | 27 | 44 |

| 1 1/4" x 1" | Rp 1" (1.33 inches) | R 1 1/4" (41.91 mm) | 19 | 27 | 44 |

| 1 1/2" x 1/8" | Rp 1/8" (9.73 mm) | R 1 1/2" (47.81 mm) | 17 | 25.5 | 50 |

| 1 1/2" x 1/4" | Rp 1/4" (13.16 mm) | R 1 1/2" (47.81 mm) | 19 | 29 | 50 |

| 1 1/2" x 3/8" | Rp 3/8" (16.66 mm) | R 1 1/2" (47.81 mm) | 18 | 30 | 49 |

| 1 1/2" x 1/2" | Rp 1/2" (20.96 mm) | R 1 1/2" (47.80 mm) | 19 | 33.5 | 50 |

| 1 1/2" x 3/4" | Rp 3/4" (26.44 mm) | R 1 1/2" (47.80 mm) | 19 | 28 | 50 |

| 1 1/2" x 1" | Rp 1" (1.33 inches) | R 1 1/2" (47.80 mm) | 18 | 27 | 50 |

| 1 1/2" x 1 1/4" | Rp 1 1/4" (41.91 mm) | R 1 1/2" (47.80 mm) | 19 | 27 | 50 |

| 2" x 1/8" | Rp 1/8" (9.73 mm) | R 2" (59.61 mm) | 19 | 31.5 | 61 |

| 2" x 1/4" | Rp 1/4" (13.66 mm) | R 2" (59.61 mm) | 19 | 31.5 | 61 |

| 2" x 3/8" | Rp 3/8" (16.66 mm) | R 2" (59.61 mm) | 20 | 31.5 | 61 |

| 2" x 1/2" | Rp 1/2" (20.96 mm) | R 2" (59.61 mm) | 22 | 32 | 62 |

| 2" x 3/4" | Rp 3/4" (26.44 mm) | R 2" (59.61 mm) | 19 | 31 | 62 |

| 2" x 1" | Rp 1" (1.33 inches) | R 2" (59.61 mm) | 20 | 31.5 | 61 |

| 2" x 1 1/4" | Rp 1 1/4" (41.91 mm) | R 2" (59.61 mm) | 20 | 31.5 | 61 |

| 2" x 1 1/2" | Rp 1 1/2" (47.80 mm) | R 2" (59.61 mm) | 23 | 32 | 62 |

Advantages

AISI 316 V4A stainless steel, resistant to corrosion and aggressive media

Temperature resistant from –44 °F to 392 °F

Max. operating pressure 20 bar with water (20 °C)

Precise CNC-milled Whitworth threads according to ISO 7/1

Versatile use in industry, chemistry, food technology, and drinking water installations

Notice

The threads are not self-sealing. For installation, sealing with hemp, PTFE tape, or sealing paste is recommended.

Hersteller:

Ningbo Beiguan Technology Co., Ltd.

1-2,Building No. 7,Jin Yuan Industrial Zone, Xinpu

135322 Town, Cixi City Province, Zhejiang Province

0086-574-63636366

office@mb-fluid.de

EU-Verantwortlicher:

SIM SPÓŁKA Z OGRANICZONĄ ODPOWIEDZIALNOŚCIĄ

Krokusowa 3

46-300 Olesno

0048 660 487 951

office@mb-fluid.de