HS Code:

73269098

Lieferbar:

sofort ( 2-3 Werktage )

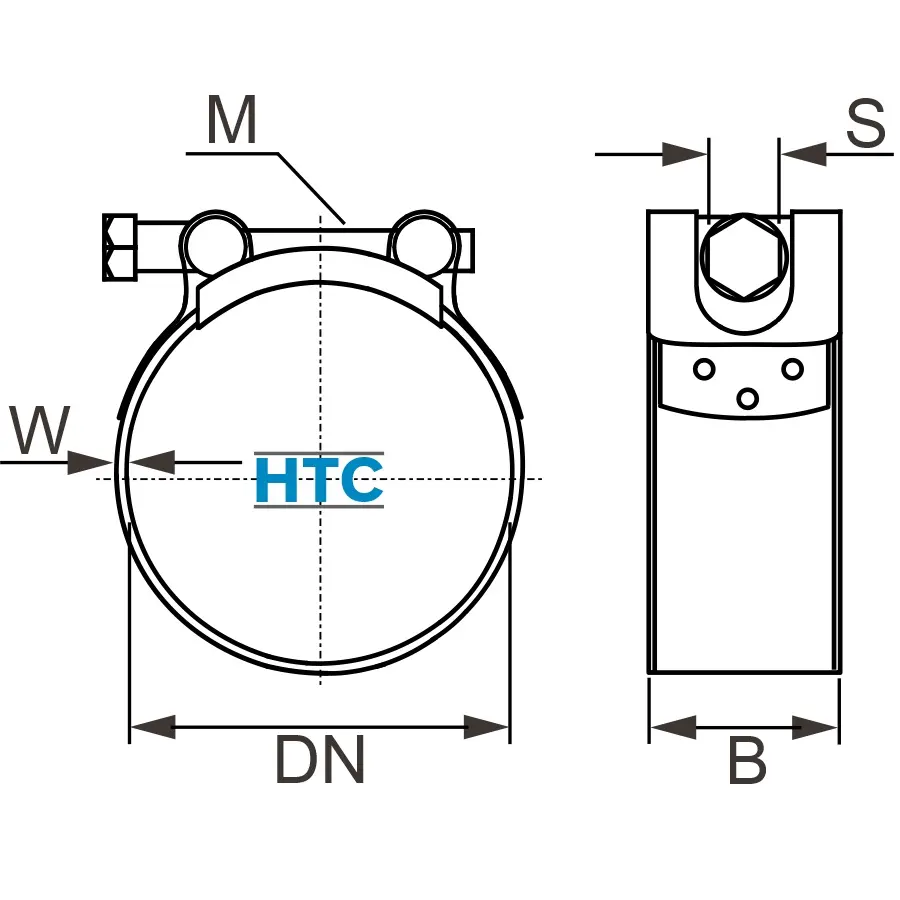

Stainless steel joint bolt clamp W4

The articulated bolt clamp (GBS) in accordance with DIN 3017 Part 3, Form C1, is designed for particularly demanding applications. It is suitable for smooth-walled suction and pressure hoses, hoses with plastic or steel inserts, and for fastening to pipes. Its robust design makes it indispensable in mechanical engineering, vehicle construction, agriculture, drainage systems, and many industrial areas.

Thanks to their W4 stainless steel (V2A, AISI 304) construction, these clamps are durable, corrosion-resistant, and reliable even under high mechanical stress.

Technical features

Width: 18–26 mm (depending on size)

Material: Stainless steel W4 (AISI 304), all parts made of stainless steel (strap, case, screw)

Tightening torque: 20 N·m

Breakaway torque: ≥ 30 N·m

Standard: DIN 3017, Part 3, Form C1

Design: robust industrial quality

Note on assembly

High tensile forces are generated during tightening. To prevent the screw and nut from seizing up ("cold welding"), the thread should be lightly lubricated (e.g., with oil or rust remover) before tightening.

Advantages

Robust industrial design for tough applications

Made entirely of W4 stainless steel (AISI 304)

High corrosion resistance even in humid environments

Suitable for thick-walled hoses with inserts

Long service life even with frequent use

Versatile use in industry, construction, agriculture, and sanitary engineering

Table Joint bolt clamp stainless steel W4

| Variant | B (mm) | DN (inches) | M | S (mm) | W (mm) | Quality |

|---|---|---|---|---|---|---|

| 17–19 mm | 18 | 17–19 | M5 | 8 | 0.6 | W4 |

| 19–21 mm | 18 | 19–21 | M5 | 8 | 0.6 | W4 |

| 20–22 mm | 18 | 20–22 | M5 | 8 | 0.6 | W4 |

| 21–23 mm | 18 | 21–23 | M5 | 8 | 0.6 | W4 |

| 9–10 inches | 18 | 23–25 | M5 | 8 | 0.6 | W4 |

| 1–1.1 inches | 18 | 25–27 | M5 | 8 | 0.6 | W4 |

| 26–28 mm | 18 | 26–28 | M5 | 8 | 0.6 | W4 |

| 1.1–1.15 inches | 18 | 27–29 | M5 | 8 | 0.6 | W4 |

| 29–31 mm | 20 | 29–31 | M6 | 10 | 0.8 | W4 |

| 1.2–1.3 inches | 20 | 30–33 | M6 | 10 | 0.8 | W4 |

| 32–35 mm | 20 | 32–35 | M6 | 10 | 0.8 | W4 |

| 34–37 mm | 20 | 34–37 | M5 | 8 | 0.6 | W4 |

| 35–38 mm | 20 | 35–38 | M6 | 10 | 0.8 | W4 |

| 36–39 mm | 20 | 36–39 | M6 | 10 | 0.8 | W4 |

| 38–41 mm | 20 | 38–41 | M6 | 10 | 0.6 | W4 |

| 40–43 mm | 20 | 40–43 | M6 | 10 | 0.8 | W4 |

| 42–46 mm | 22 | 42–46 | M6 | 10 | 0.8 | W4 |

| 44–47 mm | 22 | 44–47 | M6 | 10 | 0.8 | W4 |

| 19–20 inches | 22 | 48–51 | M6 | 10 | 0.8 | W4 |

| 2–2.2 inches | 22 | 52–55 | M6 | 10 | 0.8 | W4 |

| 2.2–2.3 inches | 22 | 56–59 | M6 | 10 | 0.8 | W4 |

| 2.4–2.5 inches | 22 | 60–63 | M6 | 10 | 0.8 | W4 |

| 2.5–2.7 inches | 22 | 64–67 | M6 | 10 | 0.8 | W4 |

| 2.7–2.9 inches | 24 | 68–73 | M8 | 13 | 0.8 | W4 |

| 74–79 mm | 24 | 74–79 | M8 | 13 | 0.8 | W4 |

| 80–85 mm | 24 | 80–85 | M8 | 13 | 0.8 | W4 |

| 3–3.5 inches | 24 | 86–91 | M8 | 13 | 0.8 | W4 |

| 3.6–3.8 inches | 24 | 92–97 | M8 | 13 | 0.8 | W4 |

| 3.9–4.1 inches | 24 | 98–103 | M8 | 13 | 0.8 | W4 |

| 4.1–4.4 inches | 24 | 104–112 | M8 | 13 | 0.8 | W4 |

| 4.5–4.8 inches | 24 | 113–121 | M8 | 13 | 0.8 | W4 |

| 4.8–5.1 inches | 24 | 122–130 | M8 | 13 | 0.8 | W4 |

| 5.2–5.5 inches | 26 | 131–139 | ST 10 | 16 | 1.5 | W4 |

| 5.5–5.8 inches | 26 | 140–148 | ST 10 | 16 | 1.5 | W4 |

| 5.9–6.3 inches | 26 | 149–161 | ST 10 | 16 | 1.5 | W6 |

| 6.4–6.9 inches | 26 | 162–174 | ST 10 | 16 | 1.5 | W4 |

| 6.9–7.2 inches | 26 | 175–187 | ST 10 | 16 | 1.5 | W4 |

| 7 1/2–8 1/2 inches | 26 | 188–200 | ST 10 | 16 | 1.5 | W4 |

Hersteller:

Ningbo Beiguan Technology Co., Ltd.

1-2,Building No. 7,Jin Yuan Industrial Zone, Xinpu

135322 Town, Cixi City Province, Zhejiang Province

0086-574-63636366

office@mb-fluid.de

EU-Verantwortlicher:

SIM SPÓŁKA Z OGRANICZONĄ ODPOWIEDZIALNOŚCIĄ

Krokusowa 3

46-300 Olesno

0048 660 487 951

office@mb-fluid.de